Heat sealing machines are an essential piece of equipment for manufacturing facilities. They ensure packaging is safe, looks good and, most importantly, that the contents remain protected. Not only this, but heat sealers are also an invaluable tool at home, where they have a wide range of uses from preserving food to organising home goods and hobby materials.

Let’s explore how these practical machines work, what they are used for and their advantages over alternative types of packaging processes. We’ll also highlight some maintenance and safety tips to ensure optimal use of your heat sealing machine for many years to come.

The Advantages of Using a Heat Sealer

Heat sealers provide a reliable seal on many different materials to ensure that products remain in optimal condition. Here are some other benefits of heat sealers to consider before investing in one for your home or business.

Preserves Product Freshness & Quality

The airtight seal that heat sealing creates makes these machines an appealing packaging solution for food manufacturers in particular. The strong bond ensures customer satisfaction as products are kept fresher for longer with a secure, tamper-evident seal.

Improves Packaging Durability & Protection

The secure seal of a heat-welded package not only protects goods from outside elements like moisture and dust, but it’s also tamper-proof. Inconsistent seals don’t just ruin the contents of your package; they can also compromise customer satisfaction and your business’s reputation.

Energy Efficiency and Less Waste

By ensuring consistently reliable seals, heat sealing machines can reduce operational waste due to packaging errors and customer returns. Their precision also allows for the use of lighter packaging materials, thus minimising the amount of packaging required.

Cost-Efficiency Compared to Alternatives

Heat sealers are faster to use than alternative packaging methods, such as vacuum sealers, which can vastly improve productivity in your operation. Also, they are often less expensive to purchase and more cost-effective to operate.

Versatility in Packaging Materials

Heat sealers are perfect to use with a variety of packaging options, including three side seal pouches, pillow pouches, side gusset pouches, flat bottom pouches and stand-up pouches. They can be used on bags with tear notches and those without. This makes them a very customisable packaging solution.

How a Heat Sealer Works

Basic Operating Principles

Heat sealers are designed to do one simple but important job: create an airtight, watertight seal that locks in freshness and keeps out contamination, damage, and tampering.

Both vacuum sealers and heat sealers play a big role in food packaging, helping extend the shelf life of perishable goods. What makes heat sealers stand out is their ability to keep food fresh while offering more flexibility. Unlike vacuum sealers, which remove oxygen from the bag before sealing, heat sealers work by using heat and pressure to seal plastic packages.

They use electricity to generate heat through a conductive wire. When packaging is placed under a sealing bar, the edges fuse to create a weld that is water and airtight. This makes them a versatile packaging solution, suitable not only for food but for a wide range of industries.

The Different Types of Heat Sealers

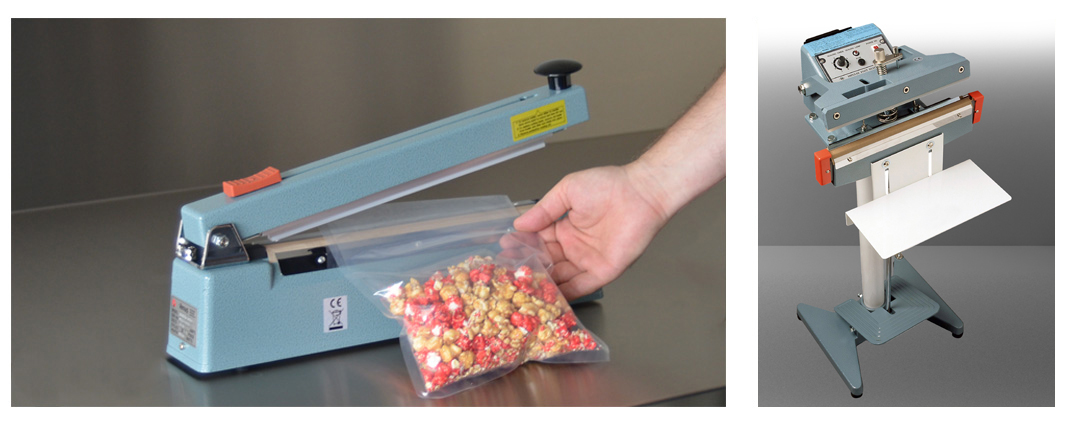

There are three main types of heat sealing machines: impulse sealers, direct heat sealers, and continuous band sealers. You can also get vacuum heat sealers that combine both suction and heat.

Continuous band sealers are most frequently used in large commercial operations with high-volume production needs. They typically feature a conveyor belt that delivers sealed packages to a collection point and are particularly popular in the food industry because they seal a wide variety of materials – from plastic bags to foil – faster than other types of heat sealing machines.

The next type of heat sealing machine is a direct heat sealer. Also known as constant heat sealers, they are capable of sealing thicker materials such as foil laminates.

Then you have impulse sealers, which apply a short burst of heat to seal thermoplastic materials like polyethylene and polypropylene. Impulse sealers don’t require time to warm up, are fast to cool and only use power when the sealing bar is lowered. This makes them best suited to smaller-batch packaging.

How to Work An Impulse Heat Sealer

- Remove the safety strap from the heat sealing machine.

- Adjust the timer to a setting that is appropriate for the thickness of the plastic you need to seal.

- Place the bagged product over the heating element.

- If using a benchtop sealer, push and hold the sealing bar closed. If using a pedal sealing machine, apply pressure to the foot pedal to close the sealing bar.

- A pilot light will glow red to indicate that the sealing process is underway.

- Hold the package in place for 4-5 seconds.

- Once the red light turns off, lift the bar and remove the sealed package.

Heat Sealer Safety Tips

Follow these tips to ensure the safe use of your heat sealing machine.

- Always inspect the equipment and power cord for damage before use.

- To prevent accidental burns, always use it on a flat surface away from flammable materials.

- Ensure that the bag is compatible before use.

- Use heat sealers on the lowest setting that gives an adequate seal.

- Don’t use excessive force on the sealing arm.

- Don’t lift the arm until sealing is complete.

- Only those who are trained to use the machine safely should do so.

Applications of Heat Sealing Machines

From coffee and chocolate to dried fruit and soups, heat sealing machines play a crucial role in the food industry. However, these versatile machines have endless applications for both businesses and home users.

At home, they can be used for hobbies, to seal clothes for travel or storage or to preserve important documents. They can also improve packaging processes for businesses that specialise in electronics, medical supplies or cosmetics, to name but a few.

For example, products that require sterilisation, such as medical equipment or cosmetics, are best sealed with heat to prevent contamination. Where vacuum sealing can interfere with the sterilisation process, heat sealing ensures that products are not affected by outside elements or subject to damage as air is expelled from packaging. Mechanical or electronic equipment that can be damaged by moisture or dust is also best protected by the heat sealing process.

In summary, any goods that require airtight packaging to preserve their integrity for transport, storage or shelf stability are best secured in heat-sealed packaging.

Choosing the Right Heat Sealer For Your Sealing Needs

Unless you have very high output requirements like those in a factory setting that require a continuous band sealer, you will likely be choosing between a direct heat and an impulse sealer. Which machine you opt for will largely depend on the type of materials you are sealing. Direct heat sealers are best for thicker materials such as foil or cellophane, while impulse sealers can be used on thermoplastic materials like polyethylene and polypropylene.

You also need to consider your seal width requirements, energy efficiency needs, and other features of both machines, such as a requirement for constant heat vs fast warm-up and cool-down times.

Maintenance & Longevity Tips

Gently cleaning your heat sealer can help prolong its life. However, as it is an electrical appliance, you should only do this once you have disconnected the power. You can use a soft, damp cloth to wipe over the machine and clean the sealing element, but ensure no water enters the internal parts of the machine.

Over time, heating elements may wear out and require replacement by a professional to maintain optimal sealing performance. Attempting to repair electrical appliances can void your warranty and lead to serious injuries.

We Sell Heat Sealers For Every Setting

Whether you need to store hobby supplies at home or you’re in the food manufacturing business, a heat sealing machine can help you preserve goods by preventing contamination and damage. Ensuring an optimal seal every time, this reliable packaging solution can boost productivity and save you money.

At Pac Foods, we offer industrial-grade, manually operated bench-top heat sealers and pedestal-operated options to suit a range of requirements. Our friendly staff are more than happy to answer any questions you may have about our range, so call us today on 1800 823 200.

FAQs

How do heat sealers work?

Heat sealers use a heated element to melt the edges of packaging material, combining heat and pressure to create a strong, airtight, and watertight seal.

How long do heat sealers last?

The lifespan of a heat sealer depends on many factors, including how well it’s constructed, the quality of materials used, the frequency of use and its maintenance schedule. With proper care, cleaning, and occasional professional servicing, many heat sealers can provide reliable performance for several years.

What is the purpose of heat seal?

A heat seal creates a secure, airtight, and watertight bond that protects products from damage, moisture, dust, and tampering.